Electrical Station Terminal Blocks

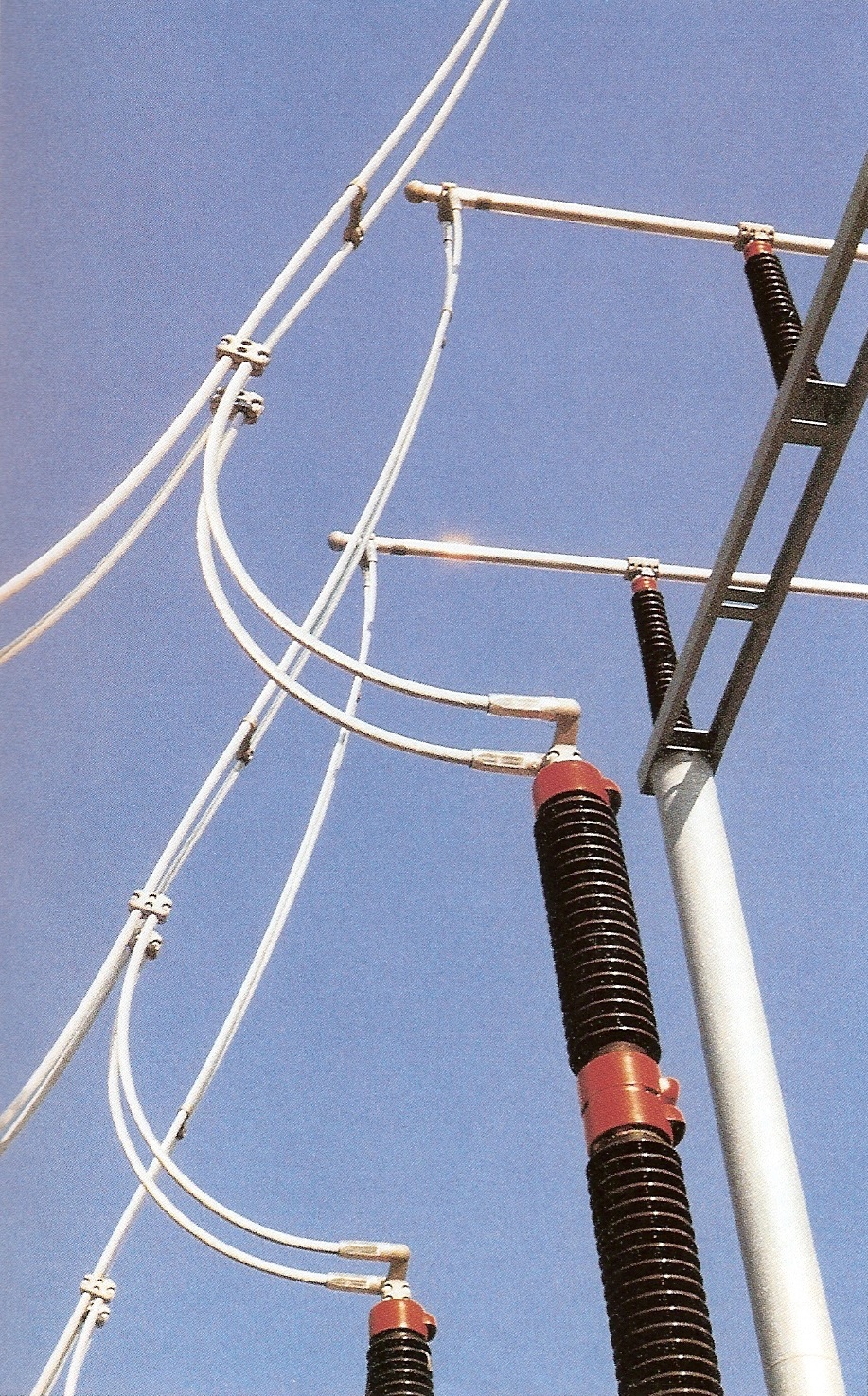

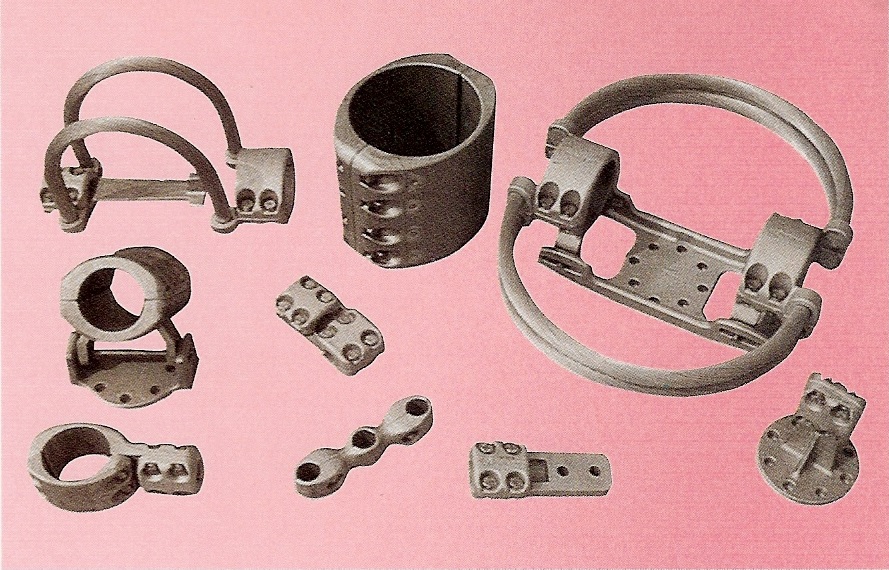

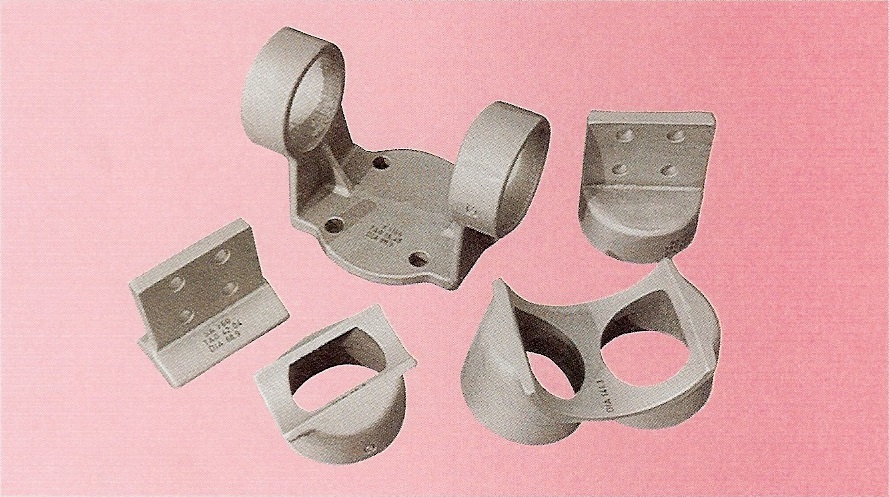

"FB" has been present for many years on the station terminal market with a complete range of products capable of solving even the most complex electrical connection problems. Our production program includes monometallic clamps in both aluminium alloy and copper alloy:

the former can be used not only in aluminium - aluminium joints, without any risk of corrosion, but also in aluminium - copper ones; the second is used for copper-copper junctions.

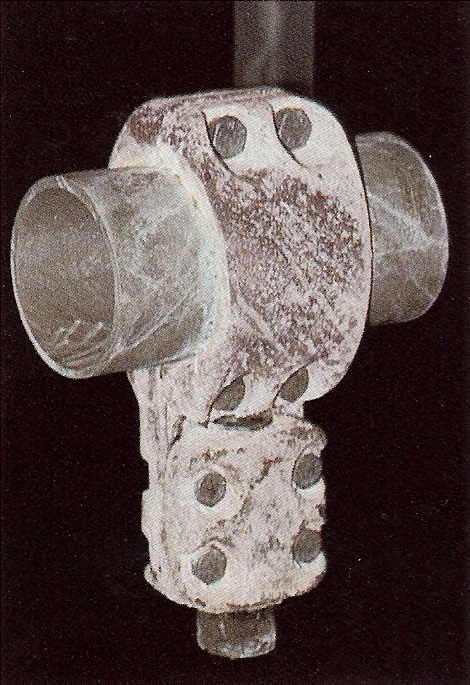

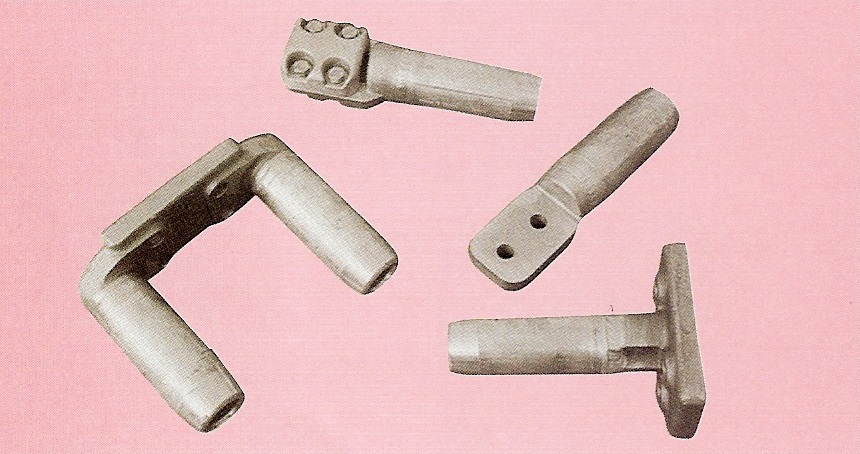

From the point of view of the methods of connection to the conductor, "FB" clamps are divided into:

- bolt clamps

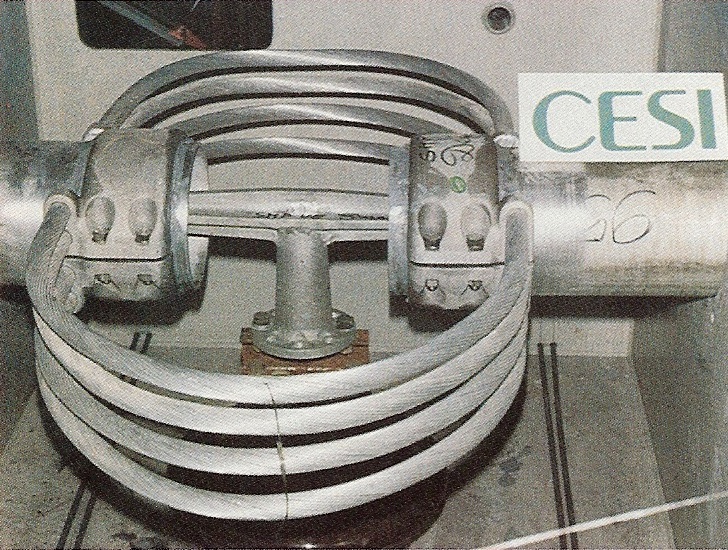

- compression clamps

- welding clamps.

All three methods have advantages and disadvantages and the choice of one or the other is linked to multiple factors of both a technical and economic nature; however, the common feature is the extreme reliability of the connection which, if carried out correctly, is able to guarantee uninterrupted service and constant performance even in the most severe operating conditions.

FEATURES

The careful choice of materials and adequate sizing ensure that with our terminal blocks the best compromise between mechanical and electrical characteristics is reached.

In particular, with the correct use of the clamp, it is possible to obtain and, more importantly, to maintain over time:

- a voltage drop at the ends not greater than that of an equal length of conductor without intermediate junctions;

- a steady-state overtemperature lower than that of at least one of the connected conductors;

- excellent resistance to corrosion;

- low potential gradients on the surface.

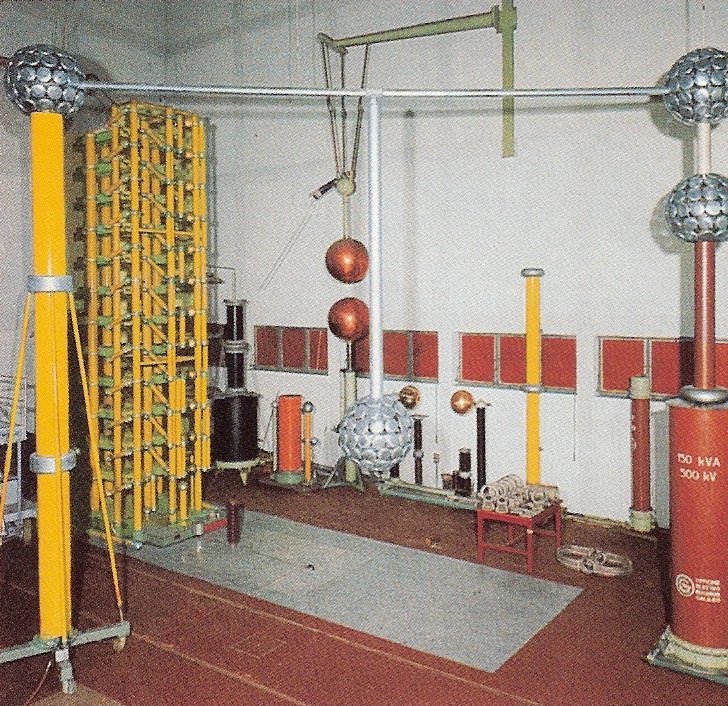

The last of the features makes it possible to use our terminal blocks to restrain the radio interference levels within the limits allowed by the standards, in systems with rated voltage up to:

- 245 KV for copper alloy clamps;

- • 420 KV for the aluminium alloy clamps (the use can be extended to 550 + 800 KV by equipping the terminals with suitable anti-effluvium shielding).

MATERIALS

The main materials used in the construction of the Officina Fratelli Bertolotti clamps are:

- aluminum alloy clamps

- for bolted and welded parts G-AL SI 7 MG MN (UNI 3599)

- for compression parts P-ALP 99.5 (UNI 4507)

- copper alloy clamps

- G-CU SN 10 (UNI 7013-1a)

- bolts

- stainless steel X 5 CR NI1810 (UNI 6900)

- Aluminum alloy (on request) P-AL ZN 5.8 MG CU (UNI 3735).

ASSEMBLY

Particular care is taken by "FB" designers to simplify the assembly operations of the terminals as much as possible, to reduce commissioning times and to have greater guarantees of correct installation which, as has been repeatedly emphasized, is fundamental for the reliability and performance of the connection.

Among the various operations, which are described in detail in the specific instructions that come with each supply, it is worth remembering, as they are particularly important:

- the careful cleaning of the parts to be joined and, above all, the removal of the oxide film on the aluminium surfaces

- the use of the special corrosion inhibitor paste (CONOX) in order to facilitate the passage of current and to seal the connection

- the use of torque wrenches in tightening bolts

- the adoption of the MIG welding method in the assembly of the welding clamps (it is the most suitable in the plant for practical reasons).

STANDARDS

Since there is no European standard (IEC) on the subject, Officina Fratelli Bertolotti connectors are designed and built in compliance with the ENEL LM 2002 and LM 2007 specifications. Since there is no European standard (IEC) on the subject, Officina Fratelli Bertolotti connectors are designed and built in compliance with the ENEL LM 2002 and LM 2007 specifications.

These specifications are particularly severe and require a long series of tests (mechanical, thermal, artificial aging, radio interference, short-circuit, ...) to which the various connectors must be subjected in order to obtain approval.

An extensive certification of the tests performed is available, obviously on the types normally used by ENEL; however, since the design philosophy of our clamps is unique, the validity of these certificates can certainly be extended to the entire range of products.

"FB" S.p.A. reserves the right to change, without notice, one or more elements of the catalog as a result of future developments and related improvements of the equipment.